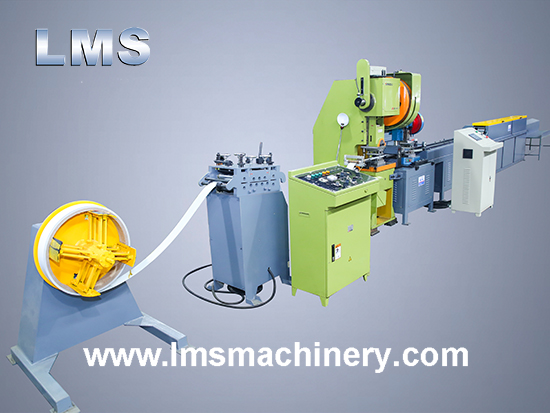

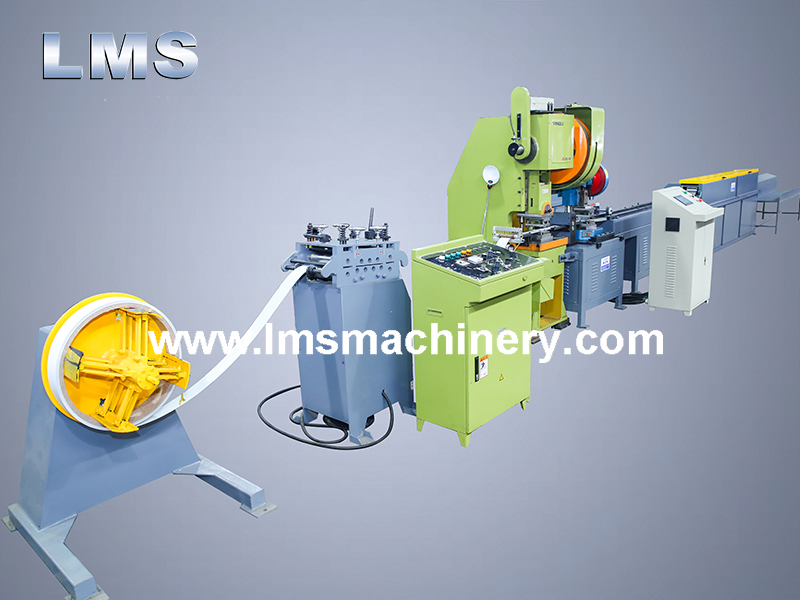

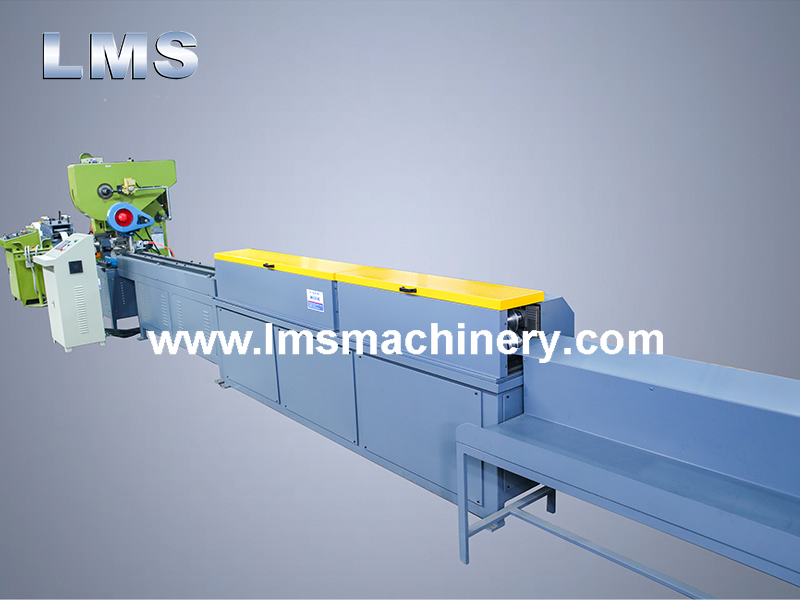

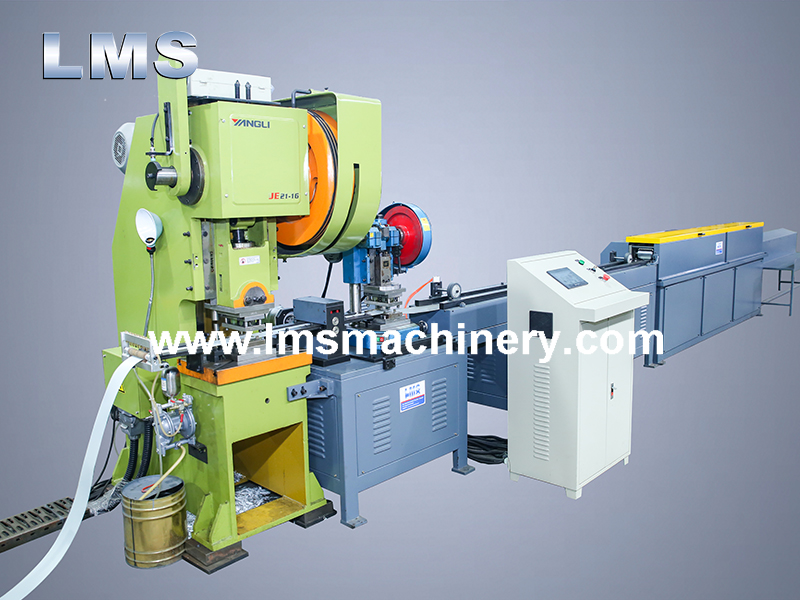

LMS Open Cell Ceiling Grilyato Production Line

LMS Open Cell Ceiling Grilyato Production Line is mainly used for the production of U15 suspended open cell ceiling grilyato. The full production line includes manual decoiler, leveler, servo feeder, power press, cutting unit, conveyor, roll forming machine, run-out table and electric control system. This production line is usually suggested to make open cell ceiling grilyato together with L strip production line, which should be ordered separately. Production speed from decoiling to discharging could be about 5 – 12 meters per minute. Other revelant metal ceiling machines could be customized as well, welcome to send samples or drawings for customization.

1. Material: PPGI / Aluminum Coil

2. Material Thickness: 0.30 – 0.40 MM

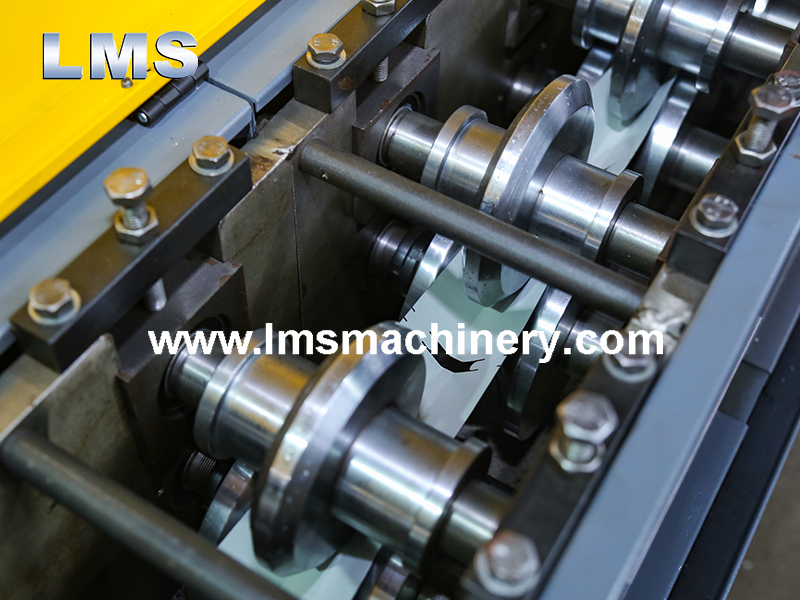

3. Profile Size: U15×37 / U15×47 MM (Main & Cross)

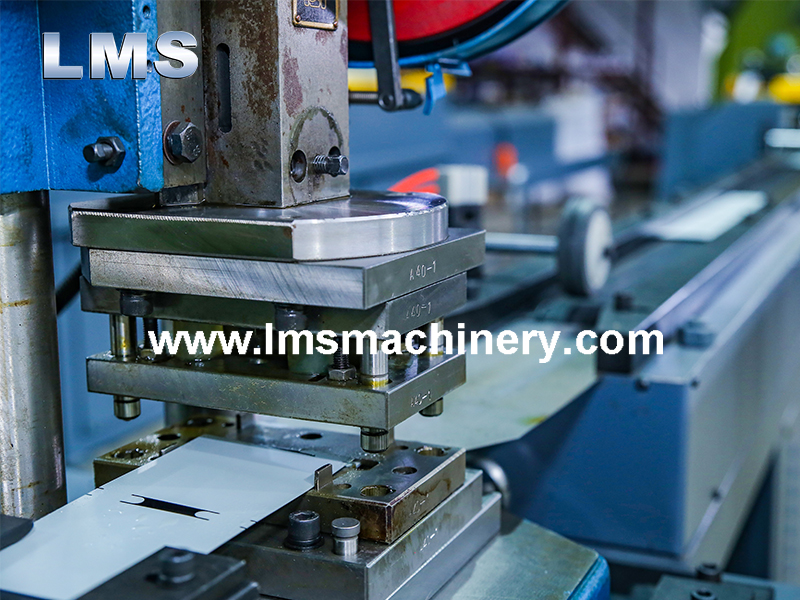

4. Punching Distance: 50 / 60 / 75 / 86 / 100 / 120 / 150 / 200 MM (8 Sizes)

5. Cutting Length: 592.2 MM (One Size)

6. Production Line Speed: About 5 M (50 MM) ~ 12 M (200 MM) / Minute

Material Coil → Decoiling → Leveling → Punching → Cutting → Roll Forming → Discharge → Finished Profile.