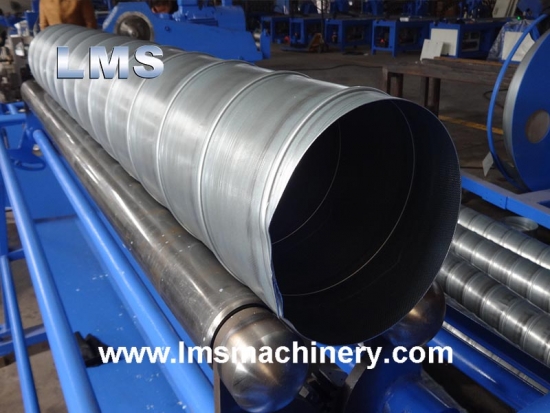

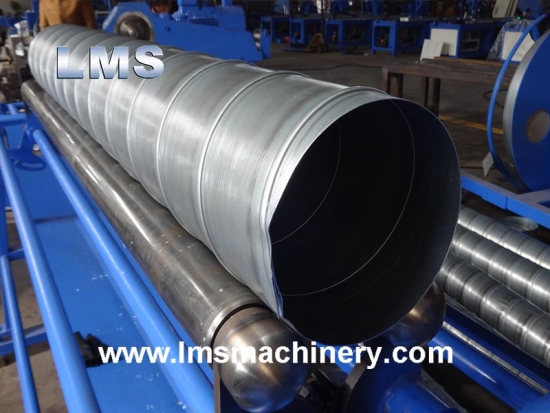

LMS Spiral Tube Forming Machine

Steel band spiral forming machine can process spiral tube with different diameters within some limites. It uses steel band instead of tube mould. By suitable adjustment, it can produce perfect tubes. The machine can be equipped with high-speed and automatic cutting device to cut tubes with requiring length.

Specification of spiral former

Name Specification

Diameter 80-1600mm

Thickness 0.4-0.3mm galvanized steel,0.4-0.8mm stainless steel,0.6-1.3mm Aluminum

Width of raw material

0.4-1.0mm thickness:137mm,1.1-1.3mm thickness:140mm

Maximum feeding speed 80m/min

Motor Hz50 V220-242△/380-420Y

Hz60 V254-277△/440-480Y

Electrical power 15kw

Weight 2000kg

Shearing system Flying shears,basic die for hydraulic belt shear-smooth and silent shearing

Size

Main part: 1950mm*1700mm*1500m

Supporting frame: 2940mm*1040mm*1220mm

Decoiler: 2000mm*1140mm*1320mm

Drive system SEW motor with converter

Supporting frame Basic worktable with pneumatic discharge(standard width of 3000mm)

Decoiler Vertical,maximum 1000kg

Others

Automatic length measurement hydraulic roller

2C Reinforced Device

1 mould of diameter of 200mm

Spiral Tube Forming Machine(roller cutting)

-SPIRO’s rimmed seam is the tightest ever tested by independent researchers on the market.

-High-quality die steel for all key components

-The unique roll mode on the drive roller makes the effort optimized.

-Special angle scissors optimize the shear.

-A special copper insert on the head minimizes friction and makes it more durable. Very precise molding roll assembly optimizes the coiling.

-Scissors use high-quality steel and have a long service life.

-The hydraulic scissors on the longitudinal shears have unique characteristics that allow optimal shearing.

-The exclusive clamping roll secures the rims.

-Efficient delivery speed of up to 80 m/min.

-Compact in size.

-Use of ductile cast iron for forming seat and bottom plate.

-Multiple protective devices with good safety.

-The special material tensioning device of the winder improves the precision and quality of the product.

-stable hydraulic system