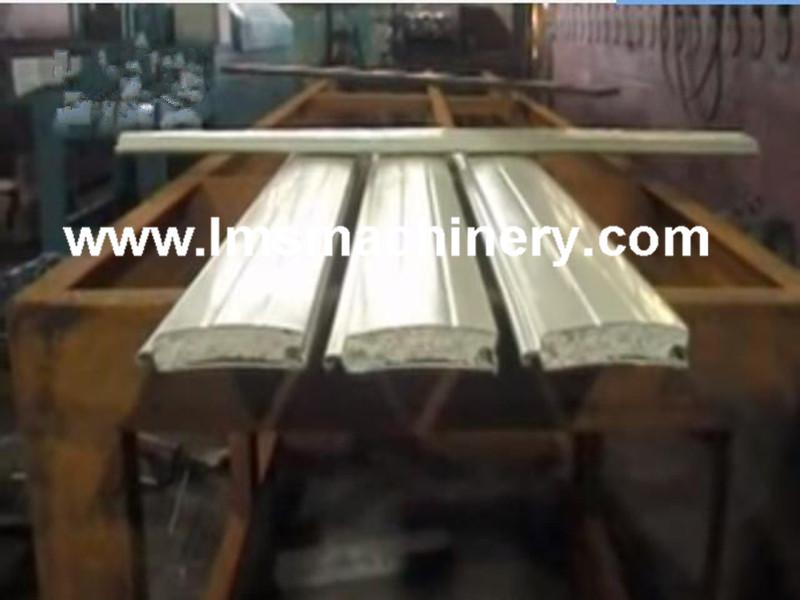

PU Compound Profile Roll Forming Machine

(Changeable Type Roll Wheel Shelf)

Product Information

(A profile: 63mm width arc, thickness: 11.4mm, including PU foam in the middle)

(B profile: 51.5mm width plane, thickness: 8mm, including PU foam in the middle)

Decoiler part

① Material outer diameter:1400mm

② Material inner hole diameter:φ400 ~ 450mm

③ Material width: 300mm

Main machine part

① Main roller wheel:26 groups ( not including mix wheel)

② Roller material: Gr15 steel

③ Heat treatment rigidity:HRC 55°~57°

④ Rolling material: colorful aluminum sheet

⑤ Rolling material thickness: 0.3mm

⑥ Product effective width: A profile 63mm arc

⑦ Roller main axis diameter: 40mm,material 45# steel

⑧ Splint thickness: 25mm

⑨ Main bearing: 60307

⑩ Main motor power: 7.5KW motor, cycloid needle speed reducer

Forming speed: 0~12m,adjustable

Shaping part

① Length:20m (each 5m)

Cutoff part

Motor power:2.2 kw

Feed material part before punching

① Length: 7m

Punch & feed material part

② Equip punch mould one set, (every time punch length about 150mm)

Pneumatic discharge shelf part

Length: 6m

Electric control

① Controlled by Mitsubishi PLC and HMI, Japanese transducer adjust speed

② voltage: 380V, 50Hz; Customized

door shutter roll forming machineoor shutter machinePU door shutter roll forming machinePU door shutter machinePU door shutter machine