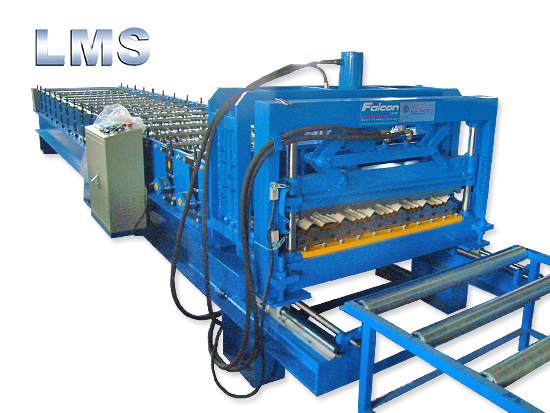

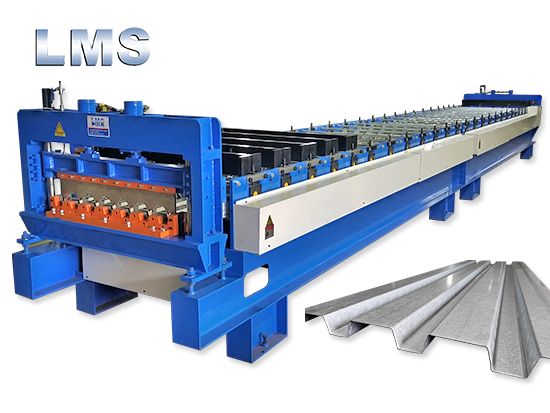

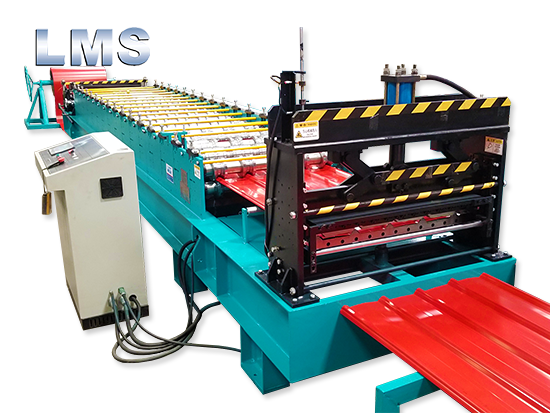

LMS Step Tile Roof Roll Forming Machine

LMS Step Tile Roof Roll Forming Machine is equipped with 10 tons hydraulic decoiler, manual shearing device before material feeding, roll forming machine, hydraulic step forming & cutting-off device, and PLC control system for metal step tiles roll forming production, convenient and easy to operate, and highly improving production efficiency.

Decoiling – Manual Shearing – Roll Forming – Step Forming – Cut Off After Sizing – Final Step Tile.

1. 10 Tons Hydraulic Decoiler:

(1) Width: 1250 MM

(2) Inner Diameter: Ø 500 – 600 MM

(3) Power: 4.0 KW

2. Manual Shearing Device Before Material Feeding:

(1) PLC Calculating And Controlling

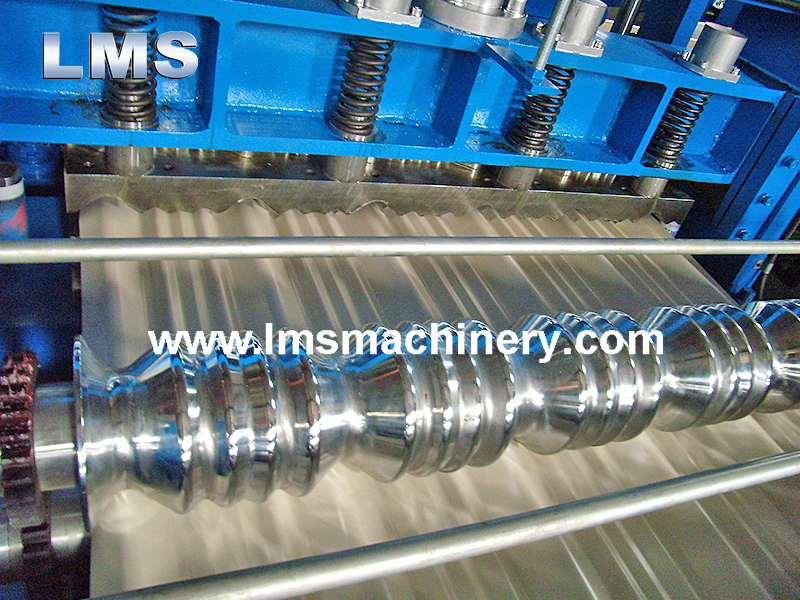

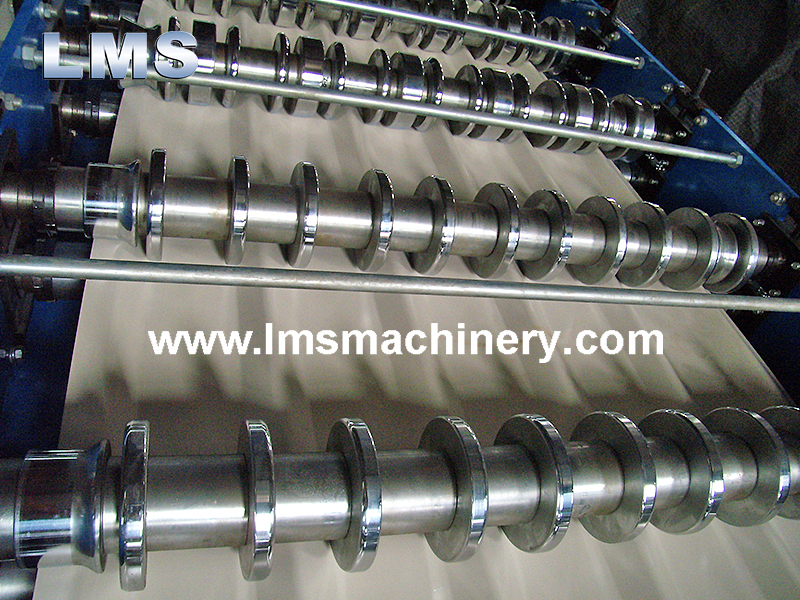

3. Roll Forming Machine:

(1) Roller Station: 18 – 24 Nos

(2) Main Shaft Diameter: Ø 80 MM

(3) Machine Sidewall Thickness: 22 – 25 MM

(4) Servo Motor Power: 5 KW

(5) Speed: 3 – 10 Meters / Minute

4. Hydraulic Step Forming & Cutting-Off:

(1) Working Table Pressure: 10 Tons

(2) With Fan-Cooler

(3) Power: 7.5 KW

5. Simple Run-Out Table:

(1) Length: 3 Meters

6. PLC Controller:

(1) Mitsubishi PLC, With 5.7” Mitsubishi Touchable Screen

(2) Japanese Frequency Converter

(3) Schneider Electronic Components

(4) Length Is Controlled By Servo Motor