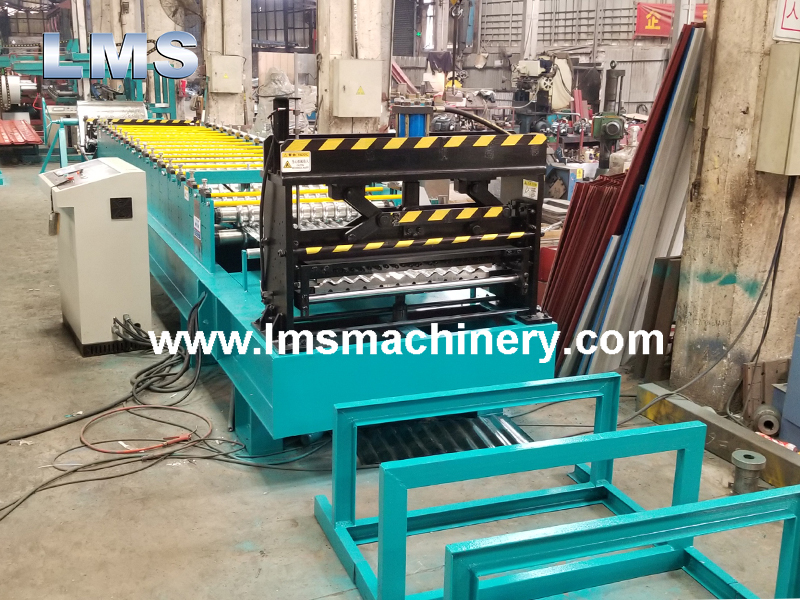

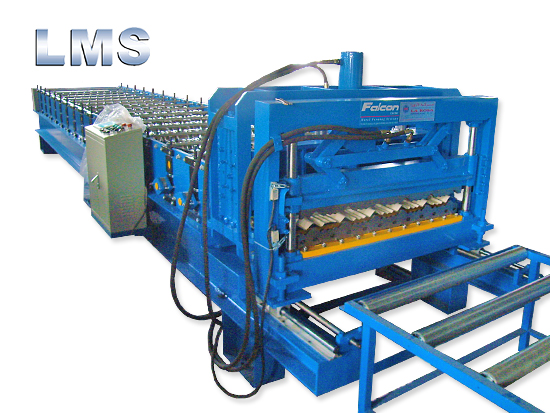

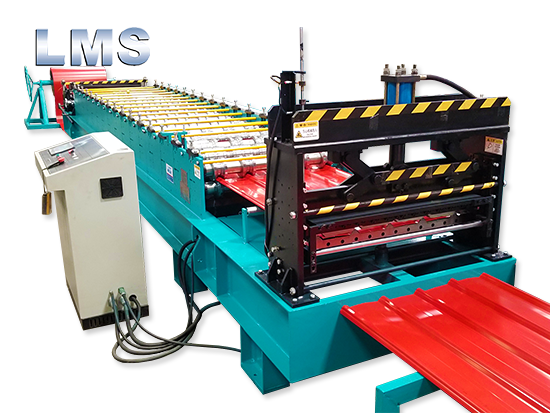

LMS Metal Corrugated Roof Tile Roll Forming Machine

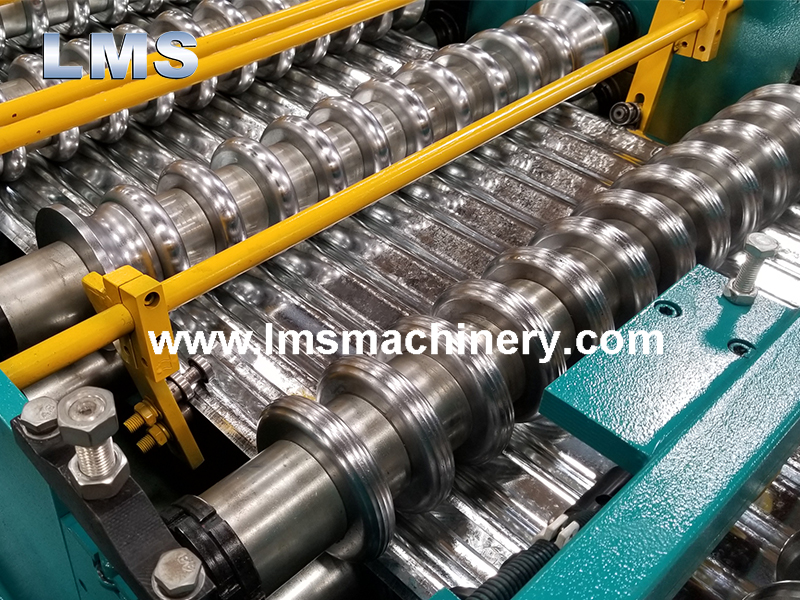

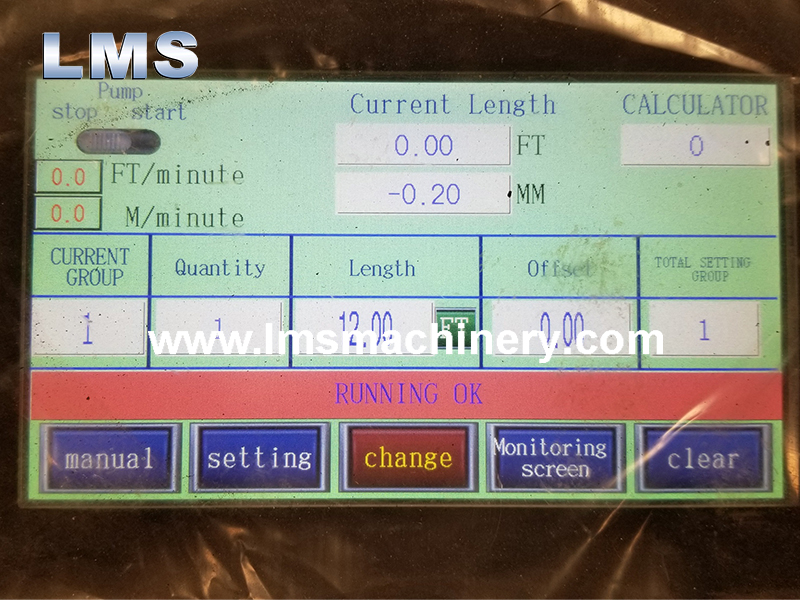

LMS Metal Corrugated Roof Tile Roll Forming Machine is a cost-effective production line with high production efficiency and stable performance. Forming rollers are designed by Germany COPRA software and plated with hard chrome on surface, service life is prolonged. Machine is equipped with PLC & electrical accessories of famous brand, such as MITSUBISHI, SCHNEIDER and OMRON, trustworthy and convenient to operate.

Waved Corrugated Steel Tile Roof Panel Making Machine Production Flow:

Material → Roll Forming → Cutting-Off → Profile.

Corrugated Pattern Roof Tile Forming Machine Composition:

1. Single Head Hydraulic-Driven Decoiler, 1 Unit

2. Manual Shearer, 1 Unit

3. Forming Machine, 1 Unit

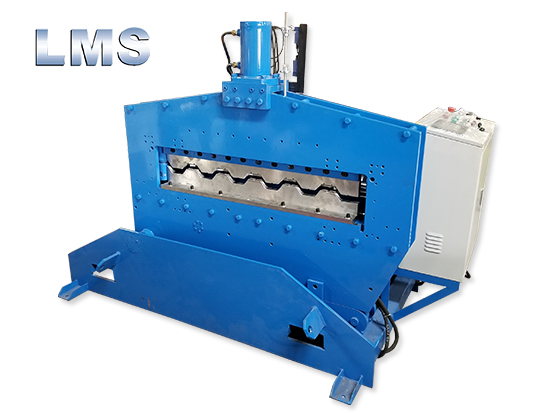

4. Cut-Off Device, 1 Unit

5. Hydraulic Pump Station, 1 Unit

6. Electronic Control Panel, 1 Unit