LMS Drawer Slide Full Automatic Assembly Machine

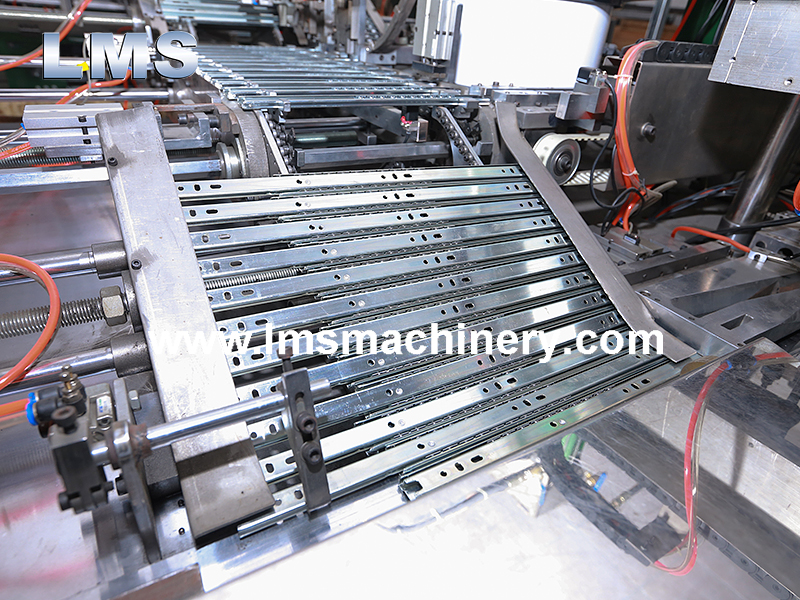

The production line is available for one-step completion of inner slide riveting, middle and outer slide assembling, and outer slide end bending, with high efficiency, high accuracy, well stability and long service life.

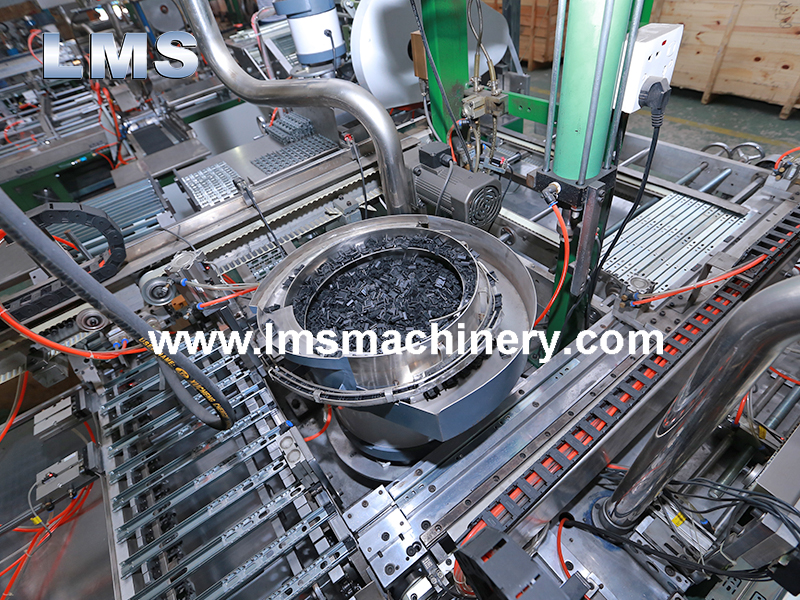

Inner Slide Riveting (Plastic Lock) — Middle Slide Assembly (Ball Cage & Balls & Plastic Stopper) — Outer Slide Assembling (Plastic Strip) — Auto Conveying — (QC Manual Adjusting) — Outer Slide End Bending (End Rubber) — Final Assembled Drawer Slides — PLC Control — (Packing).

Automatically assembly drawer slides for different lengths; high efficiency and save labor; widely applied in hardware industries.

1. Inner Slide Riveting Device, 1 Unit

2. Auto Ball Assembly Device, 1 Unit

3. Mechanical Feeding Unit For Plastic Strips, 1 Unit

4. Outer Slide Assembly Device, 1 Unit

5. Conveying Belt, 1 Unit

6. End Bending Device, 1 Unit

7. Servo Motors, 7 Sets

8. Electrical Control System, 1 Unit