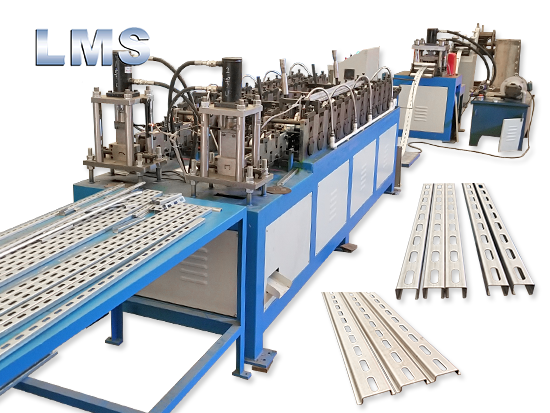

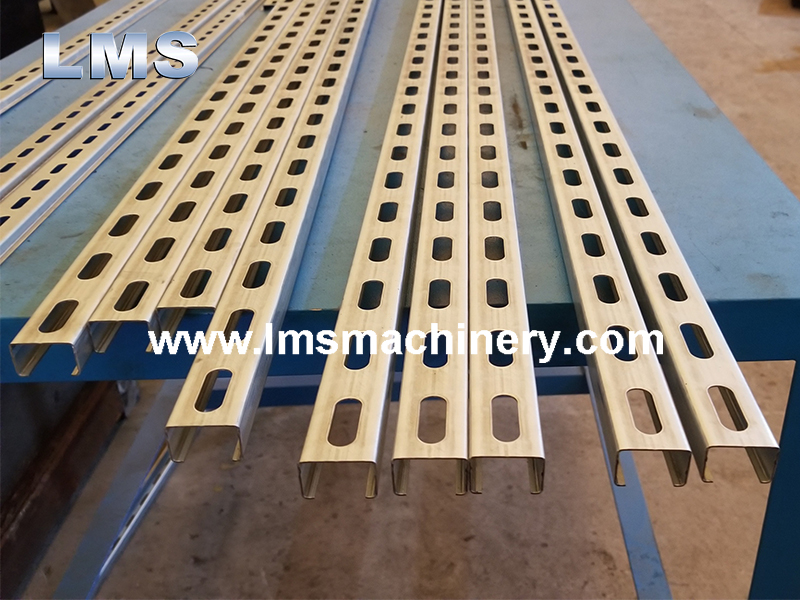

LMS CU Channel Roll Forming Machine

Production Flow:

Material – Decoiling – Leveling – Hydraulic Punching – Roll forming – Hydraulic cutting-off – Straightening – Final profile

Machine Speed (Two Sides Forming Device could not work at the same time):

2 Pieces 3 Meters Per Minute.

Components:

1. Manual Decoiler: 1 Set

(1) Max. Width: 500 mm.

(2) Manual Operating Type: Manual Expansion to Tighten the Coil.

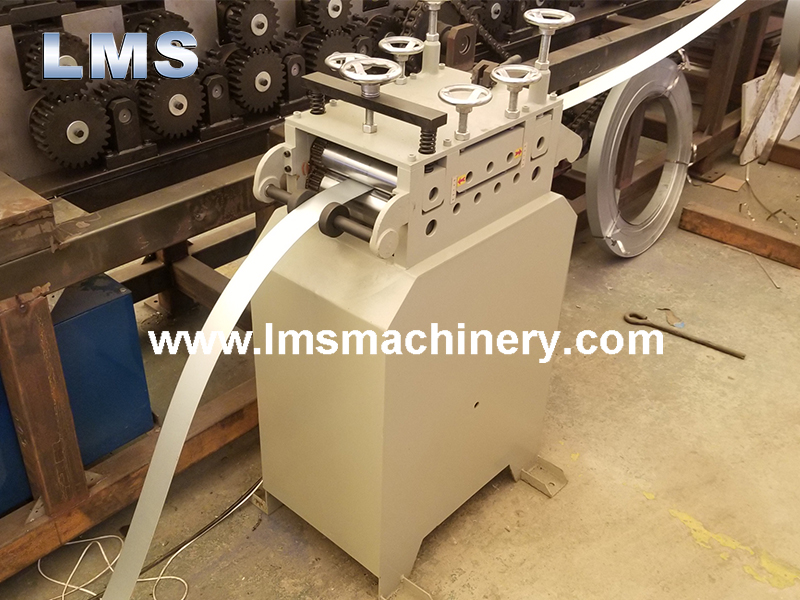

2. Leveler: 1 Set

(1) Shaft Quantity: 9 Pieces, 4 Upper + 5 Lower.

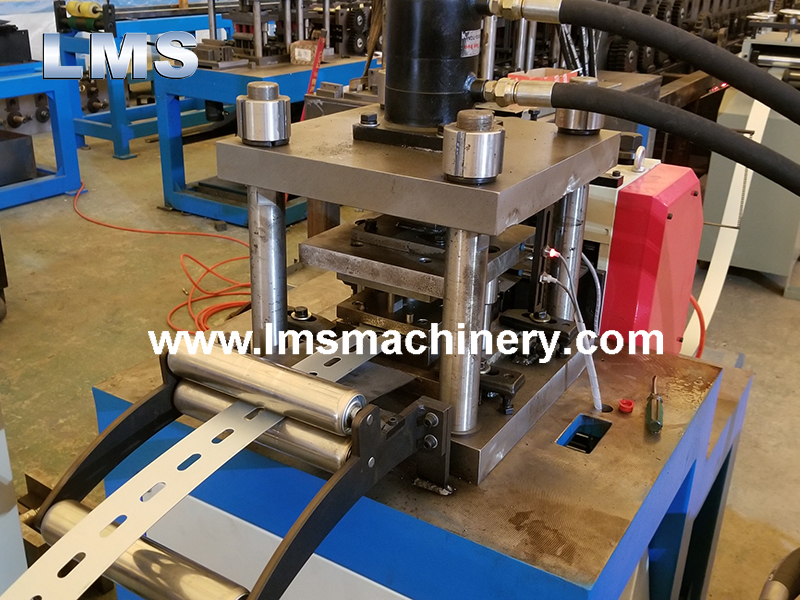

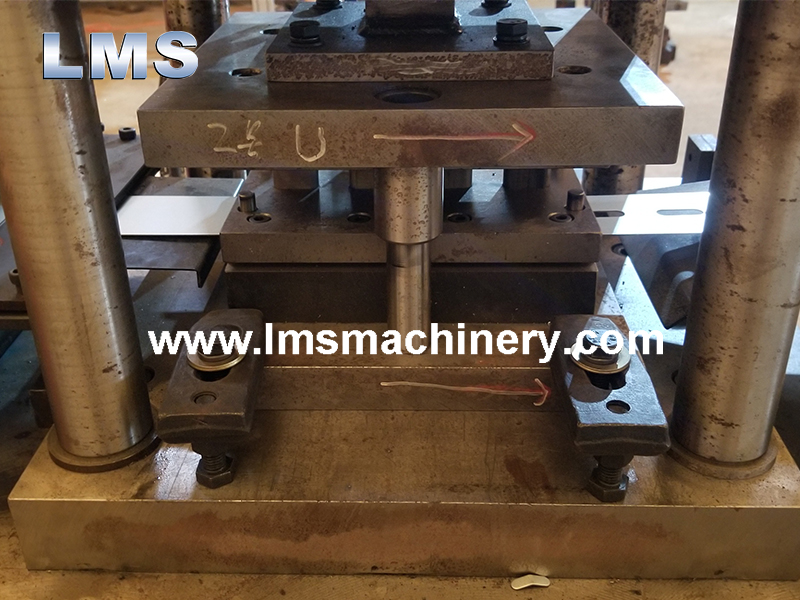

3. Hydraulic Punching Device: 1 Set

(1) Hydraulic Station: 1 Set, Independent.

(2) Punching Pressure: 13 Tons.

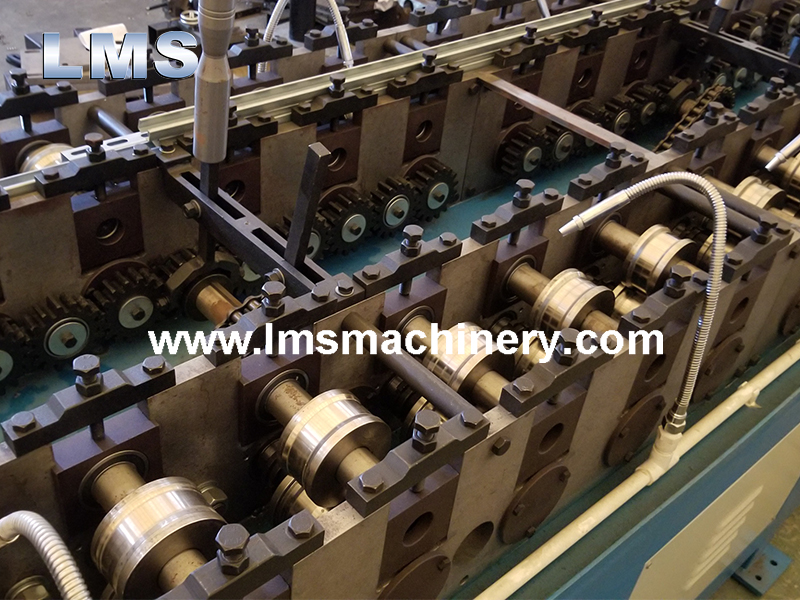

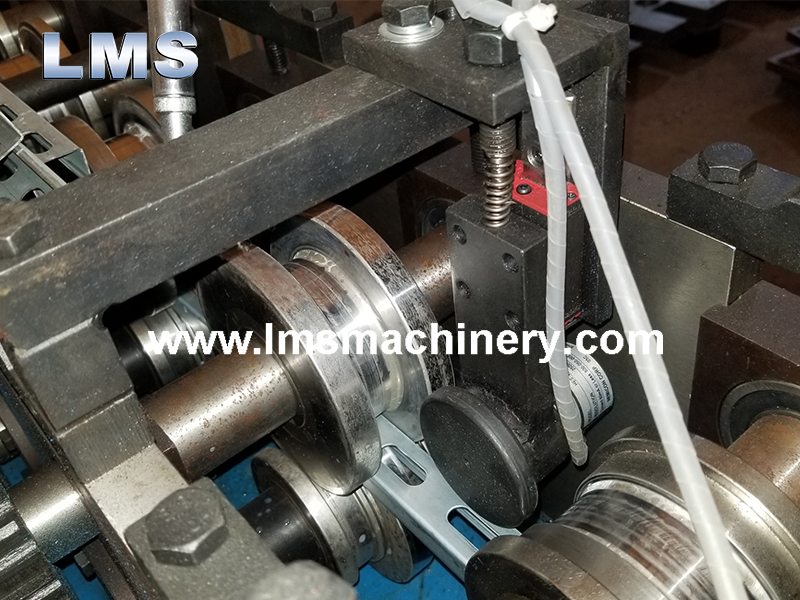

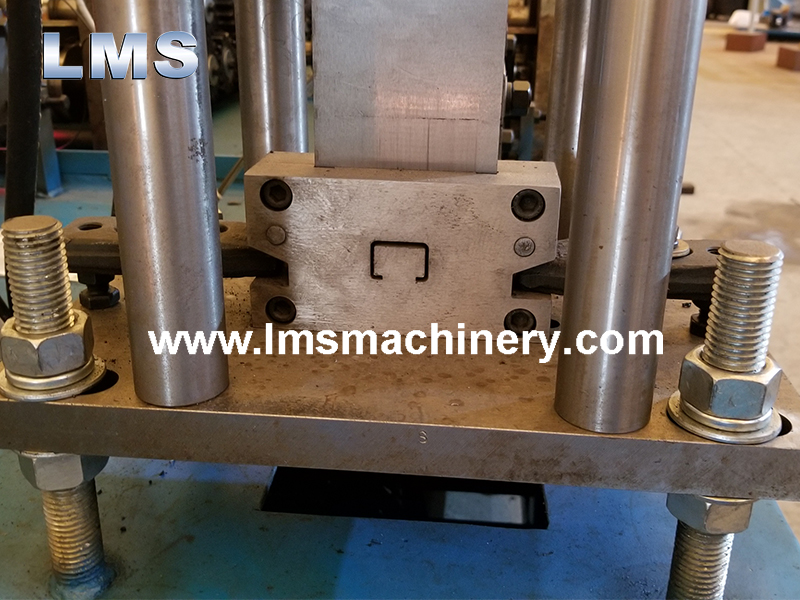

4. Roll Forming Machine: 1 Set

(1) Type: One Machine Base, Two Sides Forming Machine.

Changing Different Working Side by Clutch.

(2) Machine Base: Rectangle Tube 100×80 Welding.

(3) Rollers: 12 Nos., 5 Rollers for Straightening after Forming.

(4) Material for Rollers: Cr12MOV Steel.

(5) Hardness for Heat Treatment: HRC 58-60°.

(6) Power Transition: by Chains & Gears.

(7) Equipped with Water Coolant System

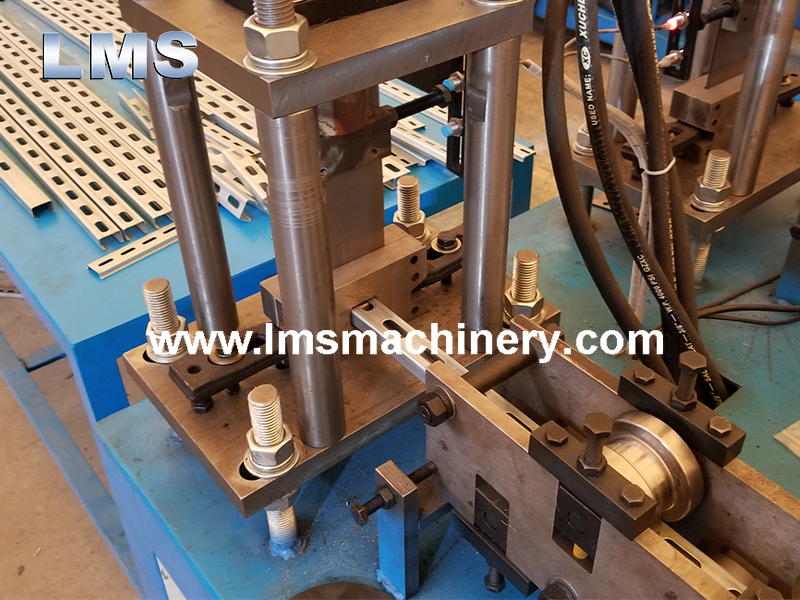

5. Hydraulic Cut-Off Device: 1 Set

(1) Hydraulic Station : 1 Set, Independent.

(2) Hydraulic Cutting Device: 2 Sets, for both Profiles.

(3) Length Tolerance Controller: by Encoder, ±1 mm.

6. Control Panel

(1) Full Sealed Electrical Cabinet: With Wind Coolant System.

(2) Power Supply: 380V, 50Hz, 3Phs.