- About

- Machine

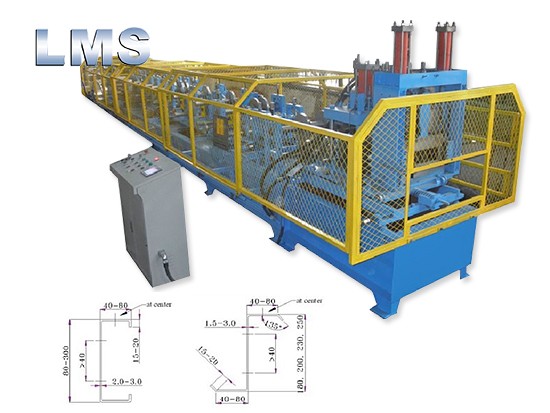

- Pallet Rack Roll Forming Machine

- Metal Ceiling & Wall Production Line

- FrameMac Light Steel House Frame Machine

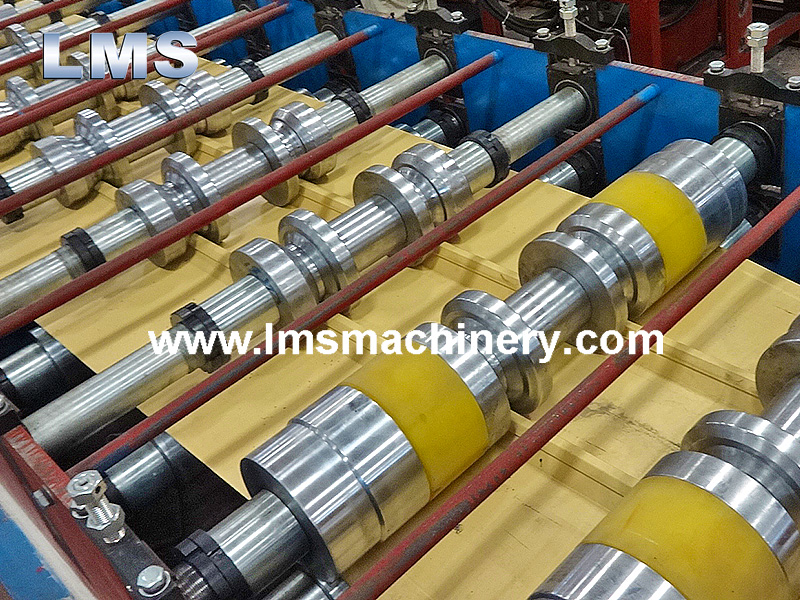

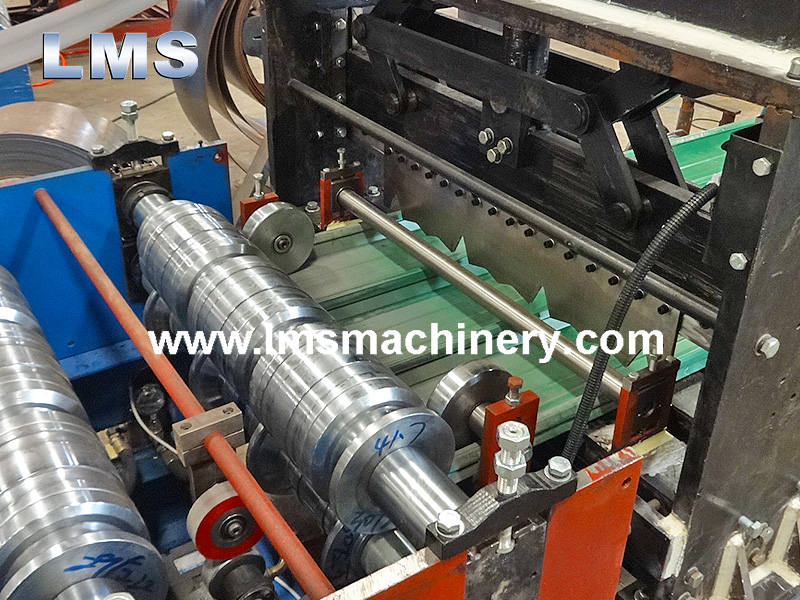

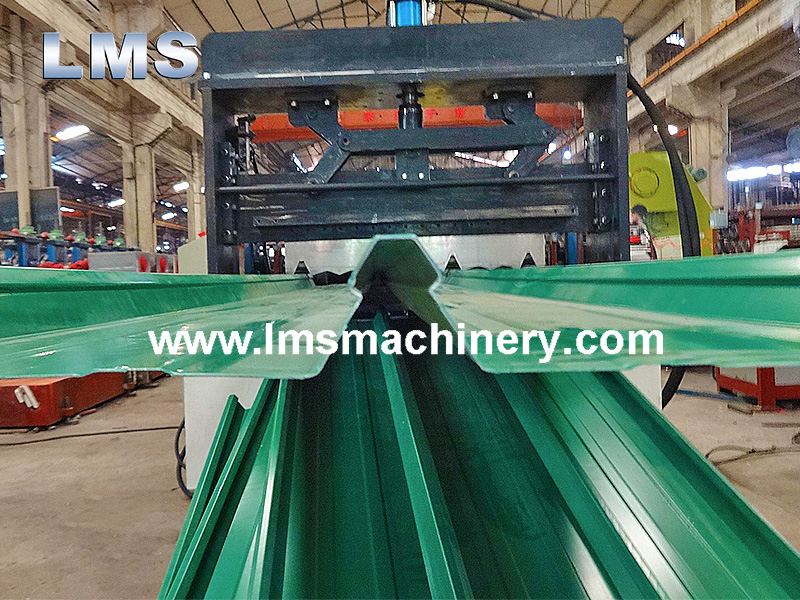

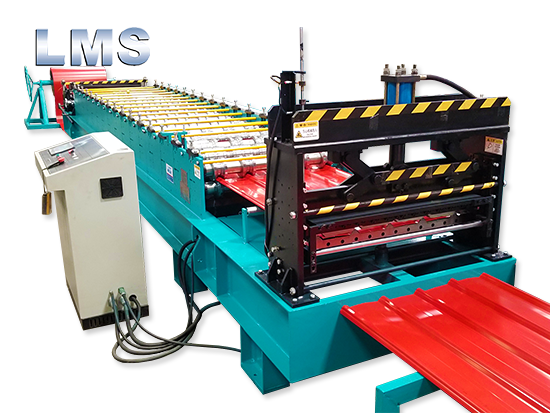

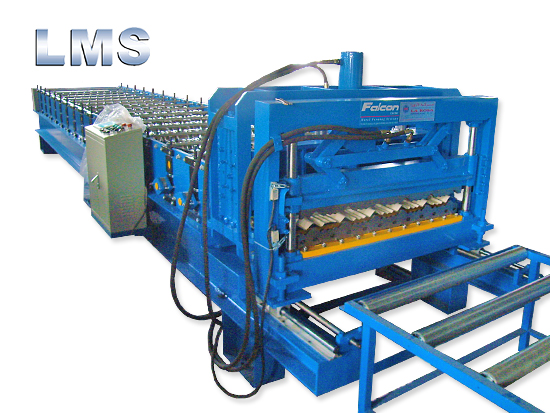

- Roofing & Purlin Roll Forming Machine

- Metal Door & Furniture Roll Forming Machine

- Electrical Support Roll Forming Machine

- Louver & Fire Damper Roll Forming Machine

- Slitting & Cut to Length Machine

- Others Machine

- Video

- Pallet Rack Roll Forming Machine

- Metal Ceiling & Wall Production Line

- FrameMac Light Steel House Frame Machine

- Roofing & Purlin Roll Forming Machine

- Metal Door & Fumitrue Roll Forming Machine

- Electrical Support Roll Forming Machine

- Louver & Fire Damper Roll Forming Machine

- Slitting & Cut to Length Machine

- Others Machine

- News & Blog

- Contact

- English

- About

- Machine

- Pallet Rack Roll Forming Machine

- Metal Ceiling & Wall Production Line

- FrameMac Light Steel House Frame Machine

- Roofing & Purlin Roll Forming Machine

- Metal Door & Furniture Roll Forming Machine

- Electrical Support Roll Forming Machine

- Louver & Fire Damper Roll Forming Machine

- Slitting & Cut to Length Machine

- Others Machine

- Video

- Pallet Rack Roll Forming Machine

- Metal Ceiling & Wall Production Line

- FrameMac Light Steel House Frame Machine

- Roofing & Purlin Roll Forming Machine

- Metal Door & Fumitrue Roll Forming Machine

- Electrical Support Roll Forming Machine

- Louver & Fire Damper Roll Forming Machine

- Slitting & Cut to Length Machine

- Others Machine

- News & Blog

- Contact

- English