LMS Door Frame Roll Forming Machine

Working flow:

decoiling-leveler-roll forming-hydraulic cutting-finished profile

A.MATERIAL AND PROFILE SPECIFICATION:

1.Materials:Q195, HCR Steel Coil

2.Material Thickness:1.2 – 2.0 mm

3.Profile Width:220.0 mm

4.Profile Height:72.8 mm

5.Profile Specification:220.0 x 72.8 x 1.2 – 2.0 mm, same as drawing

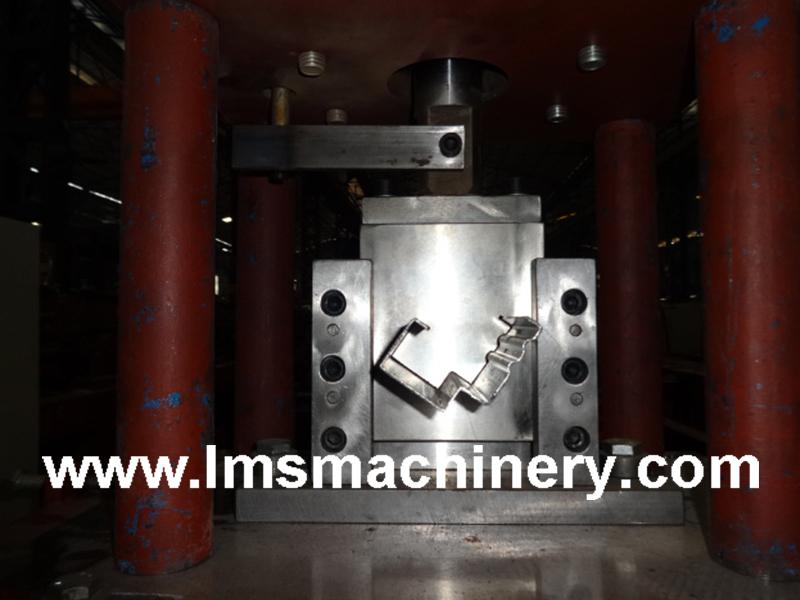

B.PRODUCTION PROCESS:

material coil – decoiling – roll forming – hydraulic cutting-off – main frame profile – PLC controlling

C.COMPONENTS

1.DECOILER:1 SET

(1)Operational Type:Manual Expansion

(2)Max. Width:400 mm

(3)Inner Diameter:Φ400 – Φ450 mm

(4)Out Diameter:1700 mm

(5)Max. Loading Capacity:2000 kgs

2.ROLL FORMING MACHINE:1 SET

(1)Rollers Stations:20 Nos, 5 Nos for Straighten Rollers

(2)Rollers’ Material:GCr15 steel

(3)Rollers’ Hardness after Heat Treatment:HRC55 – 57

(4)Main Shaft Diameter:50 mm

(5)Main Shaft Material:45# Steel

(6)Machine Frame Steel Thickness:25 mm

(7)Gears’ Material:45# Steel, after High Frequency Treatment

(8)Gears’Thickness:45 mm

(9)Main Bearing:60308

(10)Motor Power:15 kw

(11)Speed Reducer Model:QZ 400

(12)Rolling Speed:2 – 10 m / min; Adjustable

(13)Equipped Device: Water Cooler Device